The fabrication of a modern vehicle tyre is an insanely complex process.

Basically, it involves melding a range of largely incompatible materials into a hard-wearing and stable whole. A typical tyre can have up to 12 different compounds of rubber, both natural and synthetic, plus around 24 other components – reinforcement in the form of high tensile steel (both as woven belts and wires) or textiles (rayon, nylon, polyester and aramid fibres), plus fillers including carbon black, silica and chalk.

In addition, there’s a Mad Scientist’s lineup of chemicals to help keep mixtures plastic, or aid vulcanisation, or delay ageing.

Given that the bulk of a tyre’s design is directed to keeping it in perfect shape for several years and thousands of kilometres, it follows that it’ll be hell to deconstruct when its useful life is done.

But some very smart kit has been developed to tackle the problem, and in the case of Rolleston-based Tyre Collection Services (TCS) it supports a bustling fleet that roves the South Island picking up old tyres from retailers and council rubbish depots and carting them to home base where a proportion are turned into a range of very useful materials.

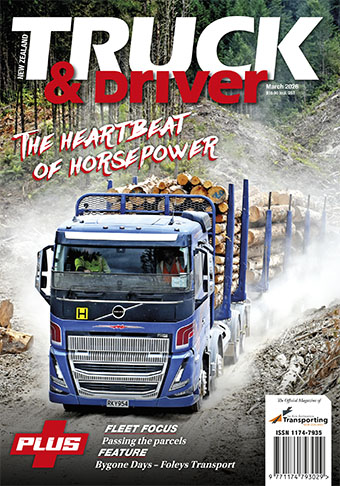

+ EQUIPMENT GUIDE - FREE

+ EQUIPMENT GUIDE - FREE